The average recurring price for a weather satellite is $290 million, while the price tag for military-grade satellites starts at least $100 million higher. Even for CubeSats and NanoSats, such as those launched via rideshare with SpaceX, the price is about $150,000. When discussing moon exploration, a recent landing by Intuitive Machines was completed with an estimated budget of $218 million. The lowest budget used so far for a lunar arrival was $74 million, utilized by India's Chandrayaan-3 mission.

Space robotics optimization opportunities

With the factors above, one wants to reduce time-to-market, development costs, and risks while receiving enhanced quality of future space missions. A proper combination of hardware and software for the mission should be selected to achieve this. However, initial prototypes, usually built with terrestrial components and off-the-shelf software, often undergo extensive adjustments to meet the constraints of space-grade hardware. On the other hand, there is an interest in reusing software stacks developed for terrestrial applications in space robotics. For example, NASA’s upcoming lunar rover, VIPER, utilizes ROS2 (Robot Operating System) and the Gazebo simulator as part of the ground segment.

Challenges in space robotics

Some of the challenges with developing space robotics applications include:

- Limited capabilities of radiation-hardened computers: Widely adopted rad-hardened chips have limited processing power. As a result, computationally intensive robotic algorithms often require a trade-off between speed and accuracy. Field Programmable Gate Arrays (FPGAs) can provide acceleration but require additional programming and integration effort. For example, Mars rover Perseverance uses RAD750 CPU units with a 133 MHz clock rate and utilizes an additional module with Xilinx V5QV FPGA for computer vision algorithms.

- Limited re-usability of earth-grade software: Only a few modern off-the-shelf robotic tools and simulation environments work directly with radiation-hardened processors and FPGAs. As a result, integrating advanced capabilities, AI, and high-fidelity simulation software with flight-ready hardware is costly.

- Gap between initial prototypes and space-grade solutions: Initial prototypes often differ from flight-ready systems. They might begin with a framework such as the Robot Operating System (ROS2) but are later modified to accommodate hardware constraints. This transition can complicate the verification process, increase risks, and necessitate additional development work.

Proposed solution

The proposed solution aims to shorten the development cycle and reduce risk by combining the following hardware and software components:

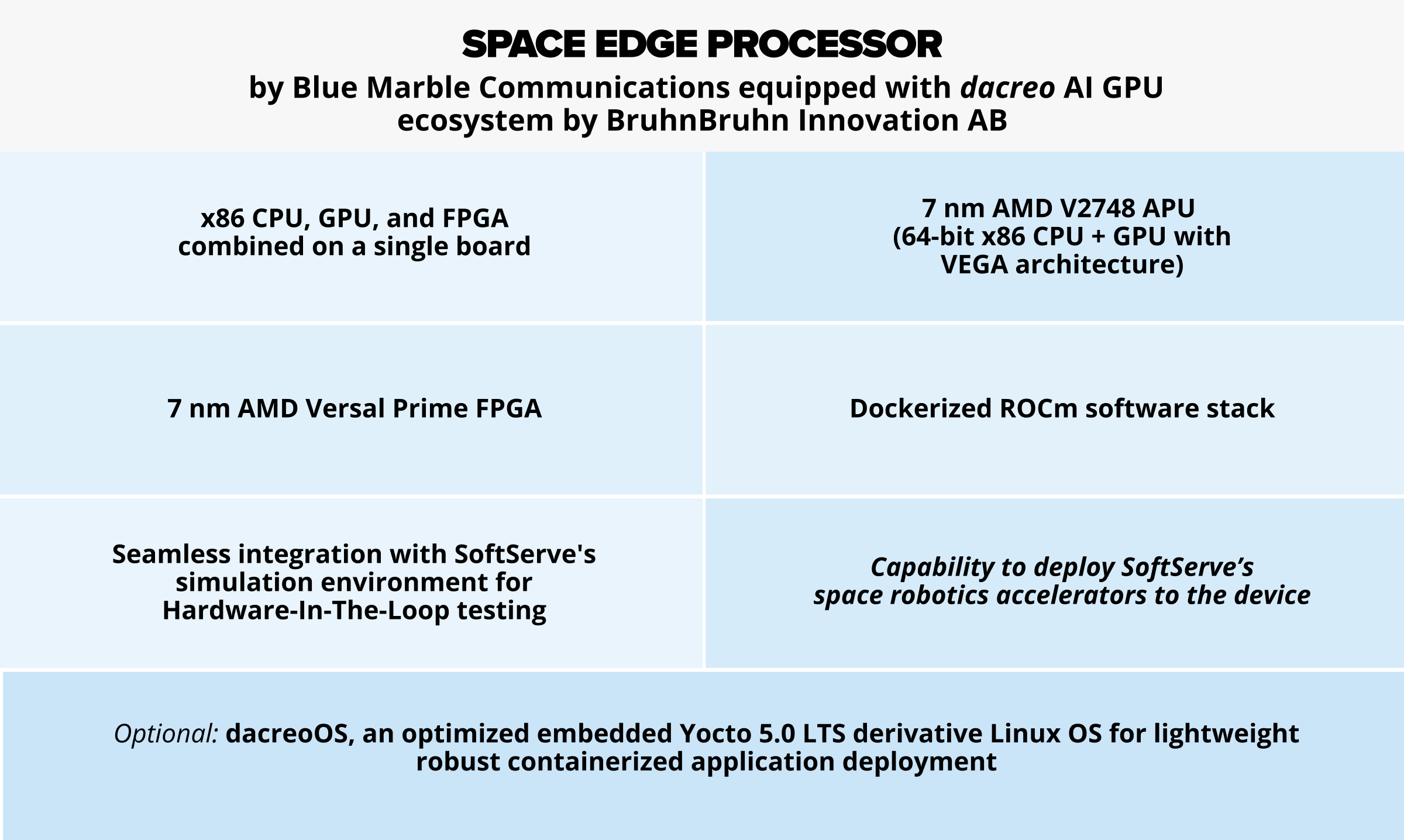

- Space Edge Processor (SEP), a state-of-the-art space-qualified, radiation-hardened, heterogeneous compute platform designed and manufactured by Blue Marble Communications, running BruhnBruhn’s dacreo software ecosystem based on Linux. SEP integrates CPU, GPU, and FPGA processing into one board. It features a 7 nm AMD V2748 APU (64-bit x86 CPU + GPU of VEGA architecture) and a 7 nm AMD Versal Prime FPGA, offering an optimized execution environment.

- Space robotics accelerators developed by SoftServe deployed on 7nm AMD APU with the dacreo ecosystem. Accelerators cover a wide range of space robotics applications, enable advanced AI and robotics use cases, and reduce development effort.

- High-fidelity simulations for space robotics developed by SoftServe, integrated on SEP-compatible hardware using the dacreo stack. The simulation environment enables fast development and hardware-in-the-loop testing. Co-simulation capabilities integrate various simulation platforms (NVIDIA Isaac, Matlab/Simulink) for interoperability.

Fig.1. Solution architecture

SoftServe’s space robotics apps run directly on Space Edge Processor-compatible hardware. The simulation environment is connected to hardware, speeding up development and enabling hardware-in-the-loop testing.

Fig.2. SoftServe’s lunar drone accelerator in a simulation environment

Use cases and applications

The solution makes it easier to develop advanced space robotics applications end-to-end. Some possible use cases include:

- Edge Processing: Powerful hardware with an optimized software stack enables multiple AI and robotics applications, such as advanced data processing, object detection, semantic segmentation, stereo mapping, or visual odometry.

- Semi-Autonomous/Autonomous Stacks: SEP’s compute power makes it possible to run sophisticated algorithms, such as the optimal control of dynamical systems with space use cases, including the control of spacecraft proximity operations for rendezvous, capture, or docking. Advanced processing capabilities can help increase the safety and accuracy of guidance and navigation methods for planetary and space vehicles. A simulation environment enables extensive testing to ensure safety and makes it possible to train operators.

- Multi-Robot Systems: The solution enables advanced data exchange and collaboration scenarios between multiple robots. Accelerators built on top of familiar software tooling make it easier to program and test complex behaviors.

Business benefits

The main business benefits of adopting the radiation-hardened Space Edge Processor and dacreo ecosystem, together with SoftServe’s space robotics solutions, include:

- Faster Time-to-Market: Leveraging the proposed combination of hardware and software can reduce the time and cost needed to develop space robotics applications.

- Easier Verification and Testing: The high-fidelity simulation environment developed by SoftServe, with online access to hardware, makes end-to-end testing more straightforward. This follows SoftServe’s simulation-first approach.

- Easier Off-the-Shelf Software Adoption: Facilitated by the Linux environment and software accelerators integrated with widely adopted robotics and AI frameworks.

- Advanced AI Capabilities: High computational power with an optimized software stack enables sophisticated AI algorithms and applications without solution-specific hardware.

- Lower Bandwidth Requirements: Enhanced computational capabilities onboard mitigate the need for downlinking data to Earth for processing.

By working with Blue Marble Communications and BruhnBruhn Innovation, SoftServe’s simulation-first approach to robotics prototyping addresses the challenges of traditional space robotics development.

If you would like to learn more about our approach, we invite you to read our white paper, which provides detailed insights into our hardware and software stack, as well as a test case evaluating computer vision algorithms on a test unit of the SEP using NASA's POLAR Stereo dataset and photorealistic simulation developed in NVIDIA Isaac Sim.

If you would like to discuss how we can assist you with your next space technology project, do not hesitate to reach out.