Recently, there has been an increase in both the desire and oppo rtunity to track personal health and fitness. Demand creates supply, so the tech market is flooding with gadgets designed to monitor our wellbeing: from calories burnt to heart rate.

In order to be precise and thus effective, each device uses a range of biosensors to monitor its owner’s health and analyze fitness training, also varying in price from several thousand dollars (BioRadio) to hundreds of dollars (Empatica) or even less (Jawbone). Regardless of cost, a great benefit (and at the same time requirement) of such devices is the fact that they rely on non-invasive methods, so here’s what different sensors and biosignals measure:

| Biosignal, sensor | What for? |

| Electrocardiography (ECG) | Heart Rate Variability, Stress, Relaxation |

| Photoplethysmography (PPG) | Heart Rate Variability, Stress, Relaxation |

| Electrodermal Activity (EDA) | Arousal, Excitement |

| Galvanic Skin Response (GSR) | Arousal, Stress level |

| Temperature and Heat Flux | Activity, Context Info |

| 3-axis Accelerometer | Movement, Steps counting |

In this blog I will show you how to build a chip solution and make a feasible prototype with the Arduino open source platform. Recently, SoftServe’s R&D team started working on a project that requires collection and analysis of biosignals, which required the ordering of specialized equipment. Time passed, but due to a bunch of issues the long-awaited equipment appeared to be unavailable for use in an R&D Lab. The results of our work were dependent on the amount and quality of the recorded biosignals, but the deadline was looming and the ordered equipment hadn’t been delivered.

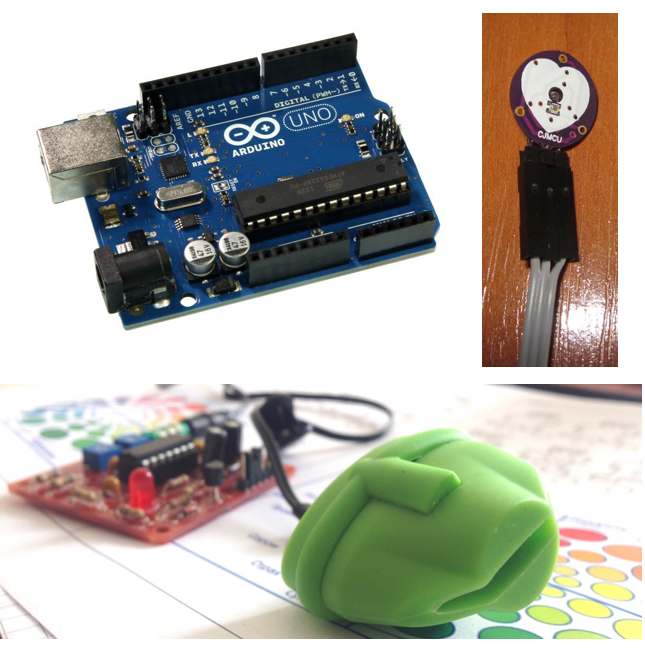

Trying to stay in control of the situation, I started looking for a worthy substitution. Having browsed all the existing electronics websites, I came across PPG sensors in a DIY section that accessed signals similar to an electrocardiogram. The price was around $10 including shipping, so I couldn’t but place an order right away. Additionally, I had two Arduino boards (Arduino Uno and Arduino Mega) at my disposal at a price ranging between $10 and $20 per piece.

Pic 6. Structure of prototype for biosignal recording

Due to its approachability, the Arduino prototyping platform opens doors to the proactive creation of future system PoCs, confirmation of its feasibility in the short term, and offers a backup when equipment orders are delayed.