Mining and Metals

Using advanced technologies to thrive in this new era of environmentally conscious mining operations.

A holistic data-driven approach to integrate and optimize surface and underground mining operations

Our strategic advisory services improve mining operational efficiencies, reduce costs, and promote sustainability. With SoftServe as a trusted partner, mining companies have embraced advanced technologies while prioritizing responsible mining practices.

Our Mining Expertise

Core Mining & Metals Capabilities

Drill and Blast Management

Through real-time data analysis, AI algorithms determine optimal drilling patterns, explosive quantities, and blast timing for improved efficiency and reduced energy consumption. Advanced technologies like drones and remote sensing enable continuous monitoring, ensuring safety compliance and prompt adjustments.

Fleet Management

Mining vehicles often face challenging road conditions, leading to shortened lifespans. By leveraging AI and ML algorithms, mining supervisors are given real-time data to make informed decisions on extending vehicle lifespans, saving costs, enhancing vehicle efficiency, minimizing landfill waste, and more, ultimately promoting sustainability and operational excellence.

Processing

Big data and AI can improve control of operations happening in the processing sites and strongly influence its cost and production rates. It can help optimize processing operations like crushing and grinding, sizing and classification, separation & concentration, dewatering & tailings management by real-time analytics of geological & processing data, detecting anomalies, and modeling/simulating different scenarios.

Resource Management

Effective mining practices rely on accurate resource management. AI and ML can help streamline stockpile analysis for resource movement forecasts, including allocating stockpile space for uninterrupted operations and scheduling train inventory movements.

Predictive Equipment Management

AI and ML algorithms empower mining companies with predictive asset management capabilities. By analyzing sensor data and equipment performance, companies can proactively schedule maintenance, reducing downtime and improving safety.

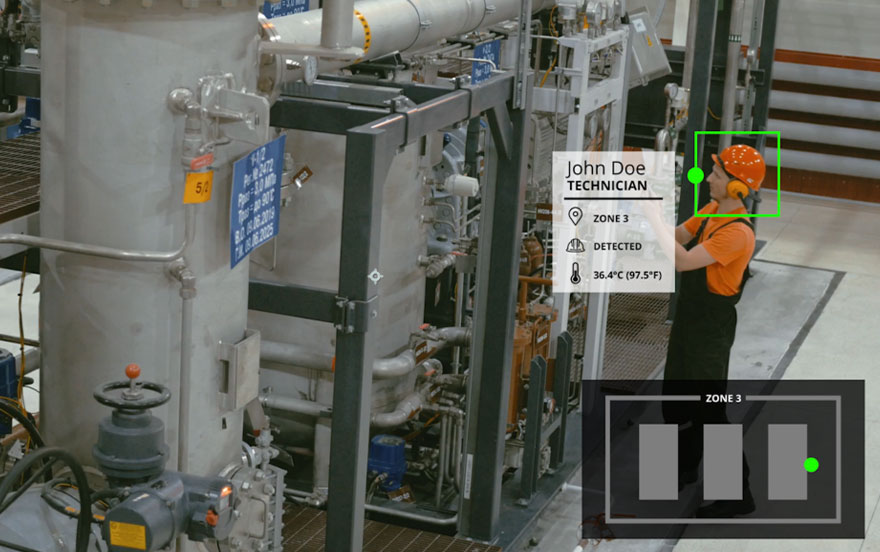

Health and Safety

Digital twins and VR simulations provide realistic training environments, allowing mining personnel to practice safety protocols and emergency response procedures virtually. This leads to a safer work environment and reduces the risk of incidents.