Boost oil production by optimizing operating parameters of ESP with AI. Phase One

Oil and gas companies are always looking for new ways to raise productivity, lower production costs, avoid downtime, and prevent asset failures. Artificial Lift Optimization (ALO) is critical to driving well production growth. Electrical Submersible Pumps (ESP) account for the largest share of the artificial lift market and play a critical role in helping energy companies realize operational excellence.

Today, reliance on manual methods for ESP monitoring and optimization is time-consuming, expensive, and prone to human error. But intelligent technologies such as Artificial Intelligence (AI), Machine Learning (ML), and Big Data can take the complexity out of operating ESPs by helping to identify opportunities, recognize problems, and optimize production rates.

An energy industry client’s success story

Our client, Vital Energy, is a leading energy company that focuses on the acquisition, exploration, and development of oil and natural gas properties. Operational efficiency and production optimization are among the key company’s priorities. Currently, Vital Energy is investing in digital technologies to ensure asset integrity, reduce operating costs, and increase production rates.

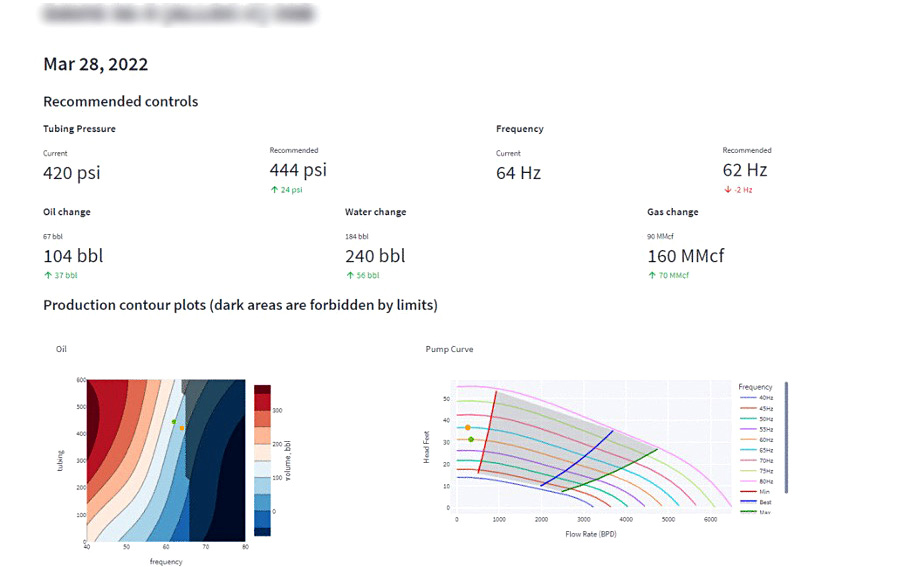

ESP-operated wells play a strategic role in Vital Energy's digital transformation strategy. New and in-service wells that run on ESP need constant monitoring and tuning of operating parameters to achieve high efficiency and production targets. Vital Energy wanted to create an AI-based solution for ESP optimization that will automatically recommend ESP operating parameters, give the ability to visualize all the necessary data, and have a way to leave feedback, input limitations, and operating constraints.

Our approach

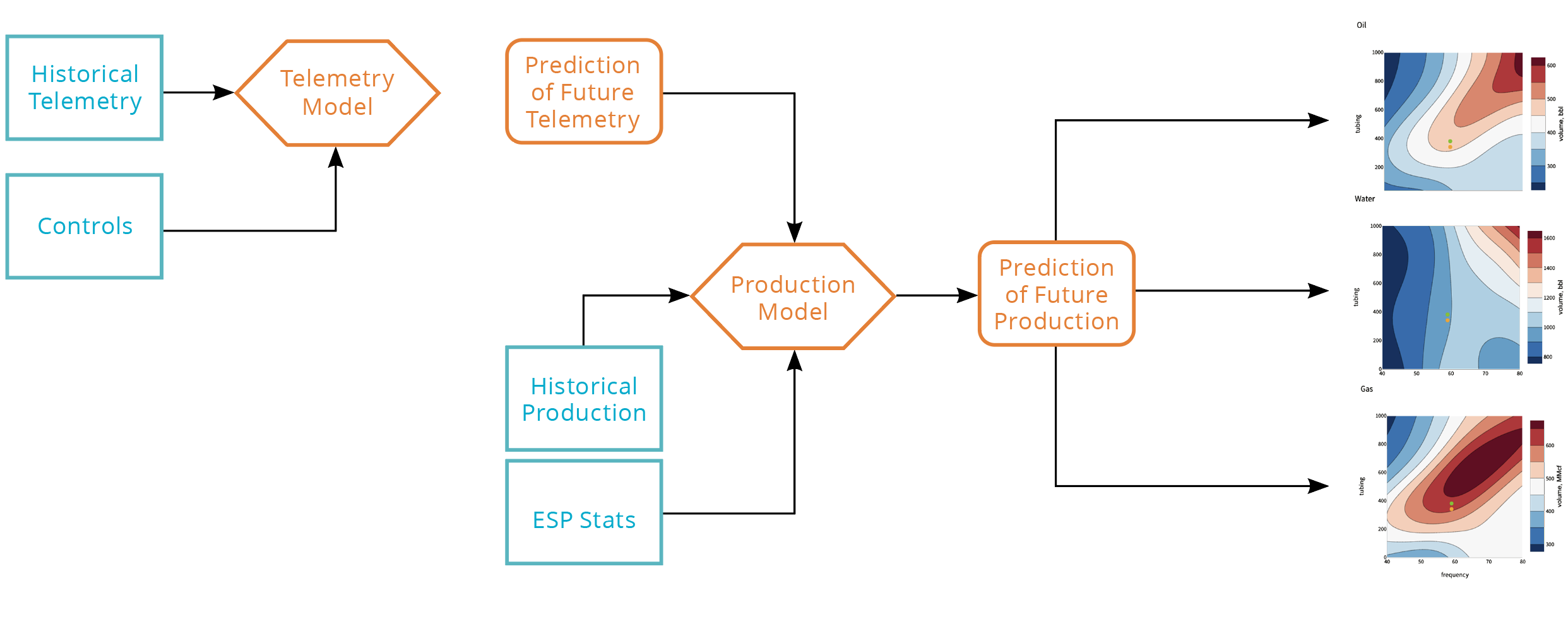

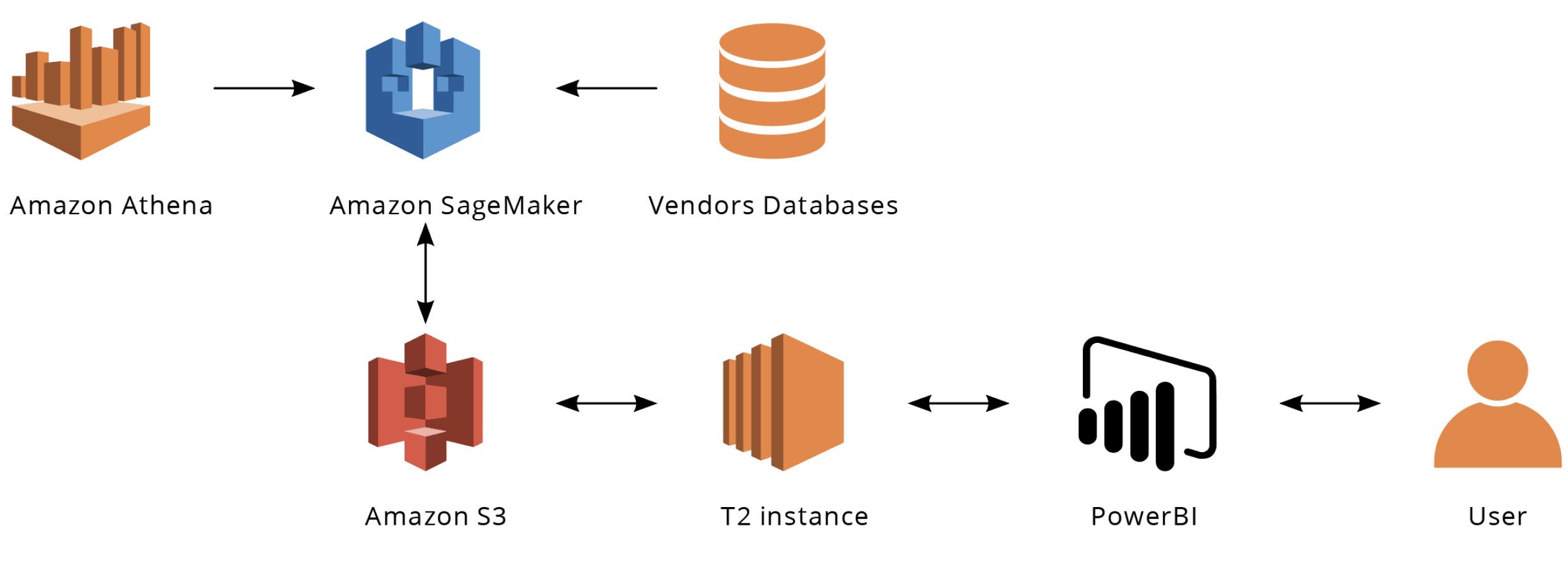

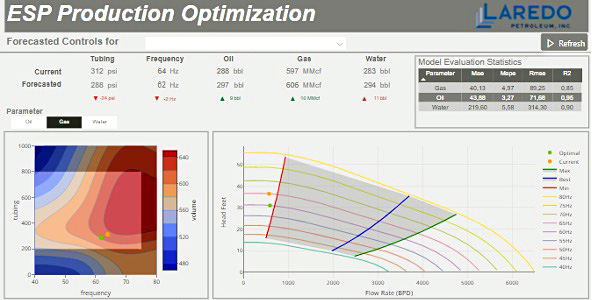

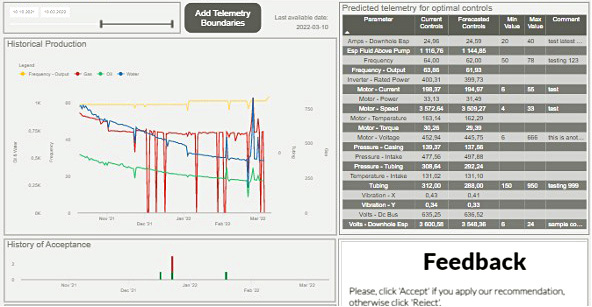

SoftServe helped Vital Energy build a comprehensive solution on Amazon Web Services (AWS) using Deep Neural Network (DNN) algorithms and optimization techniques, including extensive visualization and interpretation for end users. It models the entire system by simulating telemetry and production with different scenarios. Also, it allows Vital Energy to find the best possible controls to meet constraints such as motor temperature, voltage, intake pressure, and gas or water volume. The algorithm can be adapted to various ESP systems and provides operators with optimal daily control.

Solution outcomes:

- An ML model with high prediction accuracy of oil/gas/water production determined from data collected during several months from 50 ESPs

- An automatically retrained pipeline deployed to the AWS environment

- Interactive visualizations of simulation scenarios

- Streamlit dashboard as a prototype platform for parameter recommendations testing

- Combination of ML- and physical-based models

Value delivered

SoftServe helped Vital Energy move to data-driven ESP optimization and achieve their business goals, including:

- Real-time dashboards that provide summary statistics, forecasts, and parameter recommendations for better decision-making

- A highly flexible solution that can be adapted to a variety of ESP systems

- Reduced downtime, better maintenance practices, and reduced OPEX

- Our initial pilot achieved a production increase of ~400 BPD across 29 test wells. Later on, the client was able to get 800 BPD from around 50 wells.

- Scalability in months from 29 to more than 100 wells in production

- High accuracy of prediction of oil/gas/water production

LET’S TALK about how SoftServe can help digitally transform your company processes and effectively scale your digital strategy to the next level.

This project was completed in two complementary phases. Learn how we optimized operating conditions to further boost oil production in the second phase here.