Lack of risk awareness

Workers have no real-time information about a hazardous environment. This decreases workers’ motivation to follow safety rules. It is especially important for health problems, where unsafe behavior leads to occupational diseases over the course of months or years.

Overconfidence

Experienced workers often overestimate their own ability to assess conditions and, therefore, do not use PPE.

Macho culture

A workplace culture based on assertiveness, competitiveness, and boldness decreases workers’ attitudes toward safety issues. It has emerged in a so-called “Texas period”, where minor accidents and procedure defiance were alm ost a badge of honor.

As reported recently by the US Department of Labor, the top most frequently cited OSHA standards violated in 2018 include:

- Fall protection

- Hazard communication

- General scaffolding requirements

- Respiratory protection

- Control of hazardous energy, lockout/tagout

- Ladders

- Powered industrial trucks

- Fall protection, training requirements

- General machine guarding requirements

- Eye and face personal protective and lifesaving equipment

Training and diligence are very helpful for to reducing workplace accidents and injuries, but when it comes to bringing workers home safe, it is not enough.

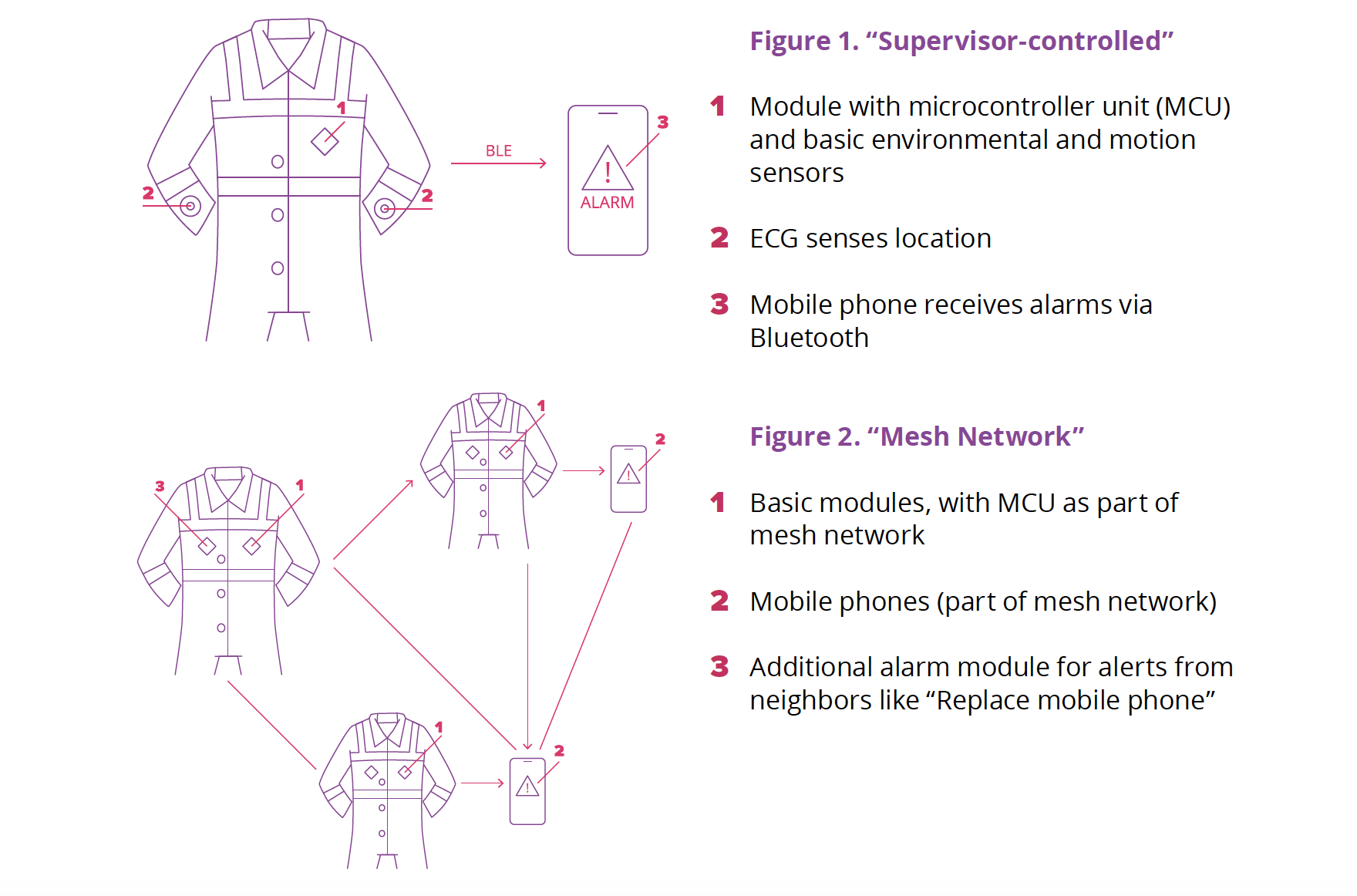

Embedded technologies integrated into smart workwear or as standalone devices enable the continuous monitoring of dangerous conditions.

Smart workwear

Based on IoT edge trends and current market analysis, research suggests workwear with an integrated wearable device allows workers to:

- Continuously monitor environmental conditions, alarming workers and their neighbors about risky and critical situations, without interrupting for measurement or for using additional standalone or mobile tools.

- Continuously monitor vital signs and behavior, alerting the closest coworker that help is needed. This monitoring enables small teams and self-employed workers to continue working without having to constantly be in one another’s line of vision.

Investigating solutions, SoftServe’s R&D team built several smart workwear prot otypes, focusing on smart workwear jackets. The team built each smart workwear jacket prototype with an embedded device and sensors, researched algorithms for detecting workers’ instant health issues and unsafe behavior (“man down” accident, heart attack), and implemented algorithms in firmware and android software. Results had in-field tests and measurements to verify performance parameters (distance, power consumption, working time, detection of accidents).